Unfortunately it’s an all too familiar story in HEMA. We have a cherished piece of equipment, and then one day everything goes bad. The arm guard cracks, the fabric starts to tear, the sword snaps in half.

We know that all our gear will eventually break with use. But when you see a brand new feder snap in its first tournament, it might cause you to ask how and why do these things break in the first place?

When looking at a rigid material (like metal and most of the plastics we are using in safety equipment) there are two factors to consider:

- How hard you hit it

- How much you hit it

Applied Load

Like everything else in engineering material science, “stress” is more important than force. Stress is the force applied, divided by the total area it’s applied over. So if you have more material it will experience less stress for the same force. I’ve written about it in the past (Force vs Pressure , What is Force Dispersion ). Also, to my shock when looking back at these articles, I’ve never made a bad pun confusing engineering material stress with inanimate objects experiencing anxiety.

As you apply more and more stress to a material it starts going through the following regions:

- Elastic – The material bends, but does back to where it was.

- Plastic – The material bends, but doesn’t go back to where it was.

- Failure – The material breaks.

We want to keep our gear in the elastic range. Plastic would be when your sword takes a set.

Impact and Fracture

Fracture is a little bit different than normal loading. It’s when you subject something to a really high energy impact for a short period of time. Like hitting something with a sword.

The normal Elastic-Plastic-Failure behavior is well defined for constant loads, like the beams holding up a building. When subjecting something to shocks it’s a little bit different.

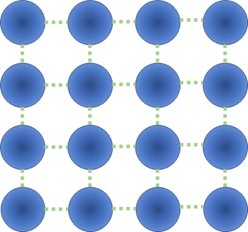

Toughness is the material’s ability to absorb energy before it fractures. Imagine we have a whole bunch of happy little atoms, sitting in their nice crystal grid. Each one is bonded to its happy little neighbors.

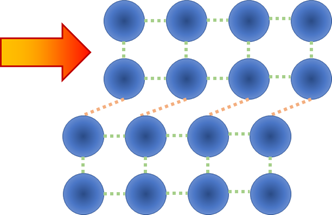

All of a sudden something comes in and hits the structure, disrupting our nice little harmony.

Those bonds in red are under a lot of stress, and eventually they are going to break. This is a material’s yield stress.

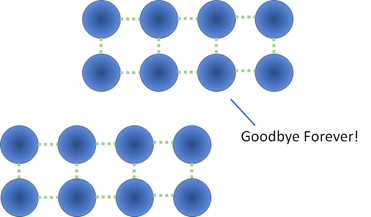

But in a tough material the bonds can reform, just with the whole structure shifted.

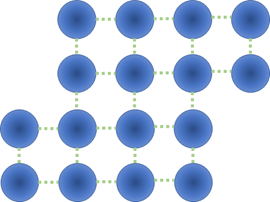

This is what happens when your sword experiences plastic deformation, aka takes a set. The whole crystal lattice has shifted into a new position to absorb the excess energy. Had it not been able to do that it simply would have snapped.

While it is desirable to have a material with bonds strong enough not to snap in the first place (a hard sword), it is even more important to have one that will allow a little bit of play before it fails. That’s why swords that are too hard tend to snap in half — the bonds of their crystal lattice are unable to shift and absorb sudden shocks.

Cyclical Loading

Swords snapping isn’t all about getting hit once, just right. You can also repeatedly load something at lower than its maximum strength and still experience failure. This is known as cyclical loading.

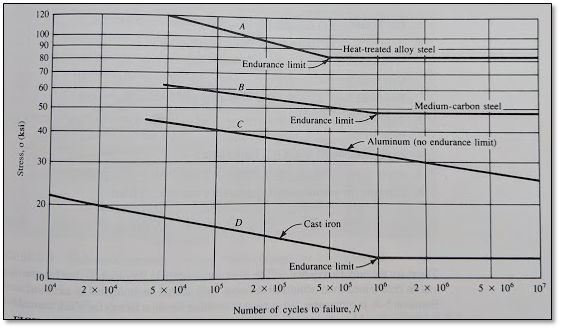

Generally, with steel you can load something up to 50% of it’s maximum yield stress as many times as you want and it will never fail to cyclical loading. This is known as the endurance limit.

If you are making steel experience more than 50% of its yield stress, it’s going to fail eventually. Even if you never go above the maximum. So all those thrusts that are getting really big bends are all adding up, until you eventually get a set.

Note that this is an engineering diagram for things like gears, and the data more or less starts at 50,000 cycles. I’m going to take a wild guess and say that most people don’t land over 50,000 stiff thrusts to their partners in sparring all that often. In HEMA we are dealing with higher forces and lower cycles, and it doesn’t quite fit these pretty models.

Crack Propagation

Cracks start life as microfractures, which eventually grow and become large and non-micro. You could call them macrofractures at that point I guess, though I’ve never come across anyone using that word.

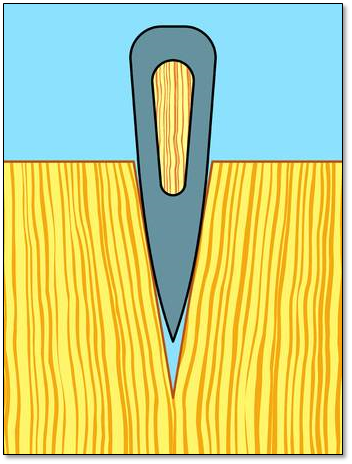

You can imagine a crack propagating through a material like a split going through a piece of wood you are chopping.

You will notice that the axe head itself is not actually cutting through the wood, the wedge is creating a super high stress region ahead of the axe, which causes the wood to split apart on its own. There aren’t a lot of bonds holding the two halves of the grain to each other, so that high stress region simply splits the wood apart.

Note that with cyclical loading, what you are doing is giving the small microfractures a small little nudge every time. They barely move, but over time it adds up and then they become all grown up real fractures of their own right. Just give them time, they are getting there at their own pace.

Inhibiting Crack Growth

Grain Boundaries

It’s basically impossible to split wood against the grain. You can’t actually propagate a crack, because every time you do it gets to a grain boundary and stops. (Though you can hack it to pieces)

The same thing happens with steel. Having smaller grains makes it harder for cracks to propagate. The microfractures can’t grow enough to become fractures, they hit grain boundaries and stop first. Imagine it like hitting a knot in the wood.

Plastic Deformation

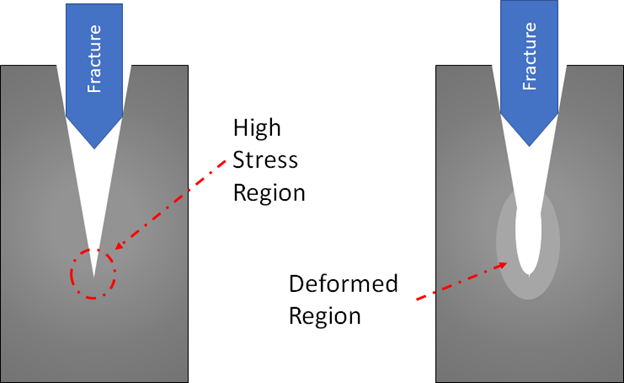

Remember our happy little atoms from above? How they can move and take energy away from a nasty old impact? Well they can do the same thing to a fracture. As the fracture propagates the material in front of it starts to deform plastically, and it takes the sharp fracture front and makes it more round.

Since we have the same force now being applied over a bigger region, what do we have?

Less stress!

Because there is less stress concentration the crack will require much more energy to spread, if it does so at all.

You can use this to your advantage. Sometimes if you have a piece of gear with a crack on in it, you can drill a relief hole right in front of the crack you can stop it from growing. I know it may seem counterintuitive that you can add a hole in a piece of gear to stop it from breaking.

On a more serious note, I have done this myself. Several years ago I had a small crack in my leg protection, which continued to grow into a not-small crack. By drilling a hole at the end of it I was able to stop the spread, and prevent having to buy a new pair.

DO NOT DO THIS ARBITRARILY. Just because you stopped the crack from spreading, does not mean that the piece of equipment is ‘safe’ or ‘fixed’. It still has a huge crack in it!!!

In this case, due to the construction of the leg guards, the crack was not in an area that was integral to the protection (thigh) and I stopped it from affecting the structural integrity of something I did care about (my knee). And duct tape to make it so I can never pinch my finger in the crack…

Wrapping Up

If you have had experience with hands on projects, a lot of this was probably intuitive. After all, physics just explains what goes on in the real world. Swords are more likely to break the more you stress them. You don’t need to take university courses to tell you that.

(I almost feel I need a tagline to go out on, so these short conclusions can feel more substantial.)